Explore the 3801

Components

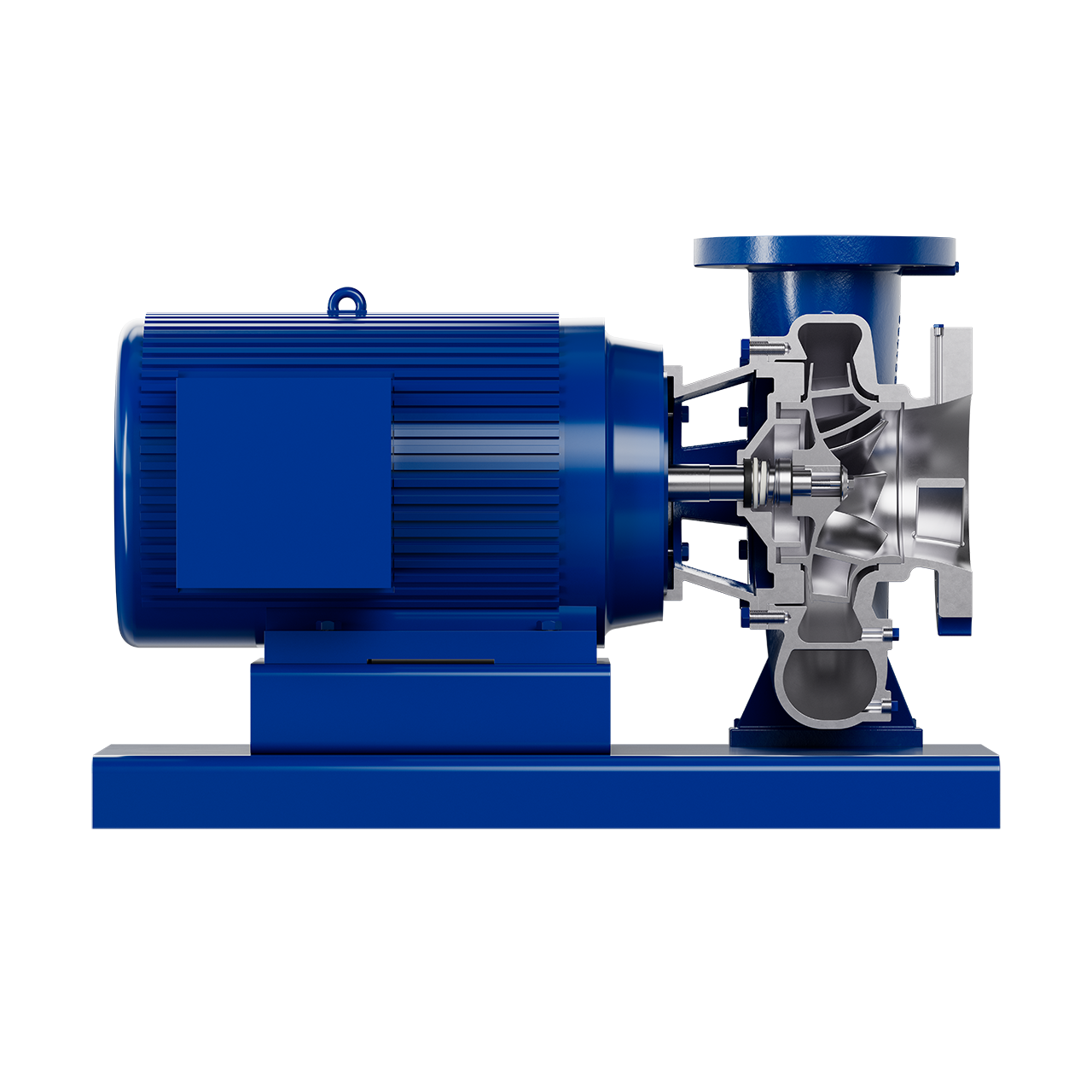

3801 - Close Coupled Legends

- Standard JM and JP motors provide low noise level pump operation

- Ductile iron casing long life with higher working pressures

- Factory Hydro test guarantees casing and seal integrity

- Double volute discharge on 4” discharge and larger to reduce bearing loads

- Suction splitter on 5” suction and larger to eliminate pre-rotation

- Casing feet for easy back pull out allows servicing of pump without disturbing suction and discharge pipelines

- Gauge taps on suction and discharge flanges

- Mechanical seal has carbon against ceramic face for optimum hot water performance. Long life is assured with 303 SST metal parts and Buna-N flexible elastomers

- Shaft sleeve to protect high strength design motor shaft

- Optional casing wear rings

- Optional seal materials

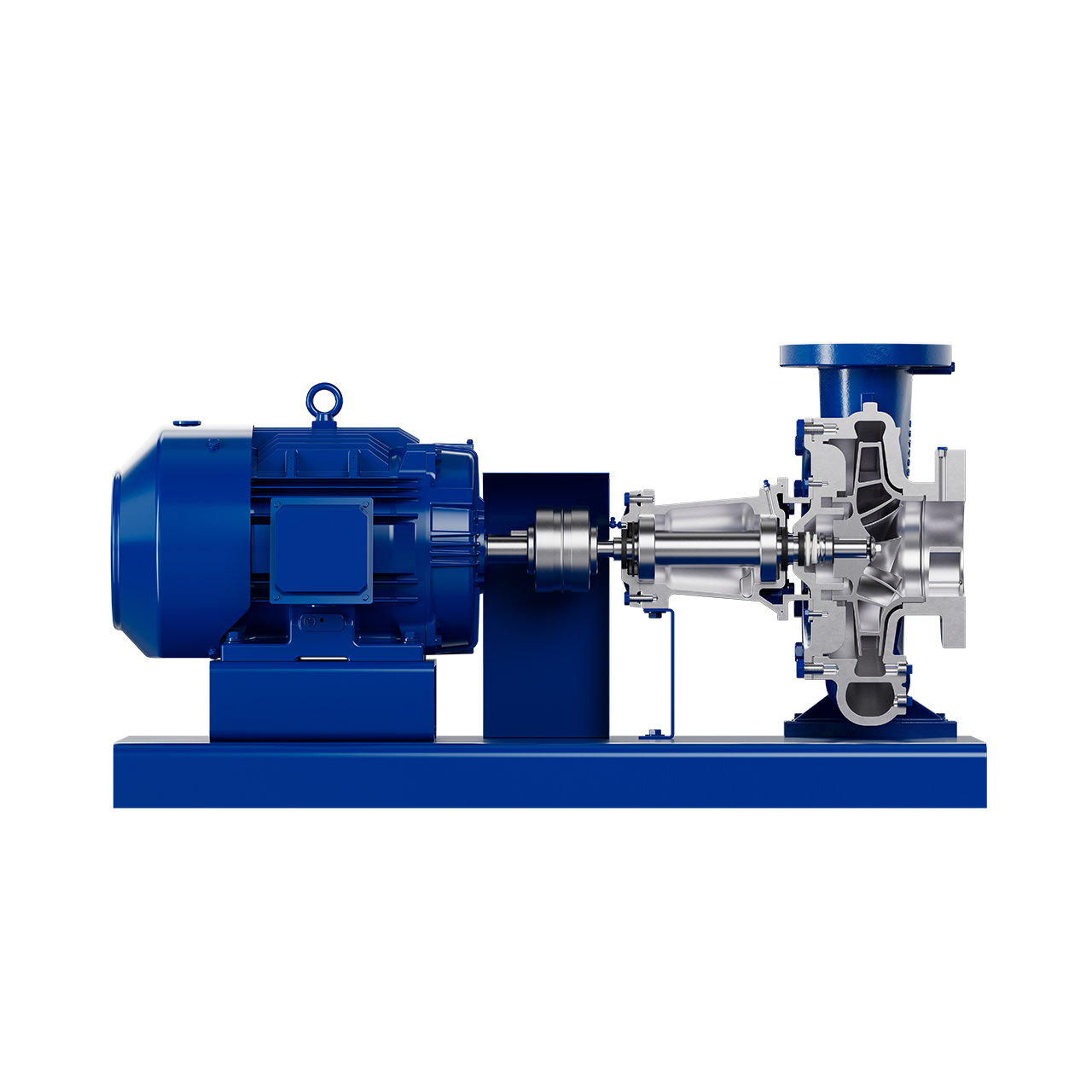

3804 – Flex Coupled Legends

- Standard T and TS base type motors provide low noise level pump operation

- Heavy duty power frame with re-greaseable bearing for long life

- Re-greaseable bearings

- Stainless steel shaft designed for minimum deflection

- Ductile iron casing provides long life with higher working pressures

- Factory Hydro test guarantees casing and seal integrity

- Double volute discharge on 4” discharge and larger to reduce bearing loads

- Suction splitter on 5” suction and larger to eliminate pre-rotation

- Casing feet for easy back pull out allows servicing of pump without disturbing suction and discharge pipelines

- Gauge taps on suction and discharge flanges

- Mechanical seal has carbon against ceramic face for optimum hot water performance. Long life is assured with 303 SST metal parts and Buna-N flexible elastomers

- Shaft sleeve to protect high strength design motor shaft

- Optional casing wear rings

- Optional seal materials

Explore the 3804

What Can You Use a Single Stage End Suction Centrifugal Pump for?

Aurora 3800 Series is best suited for the following applications:

- Building services: Provide efficient water transfer for HVAC systems, pressure boosting, and chilled water circulation.

- Industrial processes: Transfer water, process liquids, and mild chemicals in various industrial settings.

- Water and wastewater treatment: Transfer clean water or effluent in treatment plants.

- Agriculture irrigation: Deliver a reliable flow of water for irrigation systems.

- Commercial pools: For pool filtration, treatment and water movement

Videos

3801 End Suction Pump

3804 End Suction Pump

Resources

Downloads

- Aurora Models 3801 & 3804 End Suction Pump Manual

- Aurora 3800 Series Single Stage End Suction Pumps Brochure

- Aurora 3801 Specifications

- Aurora 3804 Specifications

- Aurora 3800 Series Liquid End Kits Sell Sheet

- Aurora 3800 Series End Suction Pumps Repair Parts Index

- Aurora 3800 Series Dimension Tables

- Aurora 3801 - End Suction Revit

- Aurora 3804 End Suction Revit

- Aurora Repair Part Kits & Assemblies (Legacy Models)

- Aurora 3800 Series End Suction Pumps Sales Flyer

- Pentair Aurora HVAC Portfolio Sales Flyer

- Aurora Commercial HVAC & Water Supply Pumps Brochure

- Aurora New Repair Kits Sales Flyer

- Aurora End Suction & In-Line Pumps Repair Kits and Parts Guide (NEW)