- Pool & Spa

- Pool Education & Support

- Professional Support

- Professional Pool Education & Tips

- 7 Servicing Tips For Variable Speed Pumps

Changing variable speed pump technology can present a challenge for pool professionals not in-the-know. As engineering grows more advanced, work gets easier and more efficient... but it is important to keep a few things in mind to ensure service professionals feel confident in tackling common challenges that may arise in the coming season.

-

Always Inspect

-

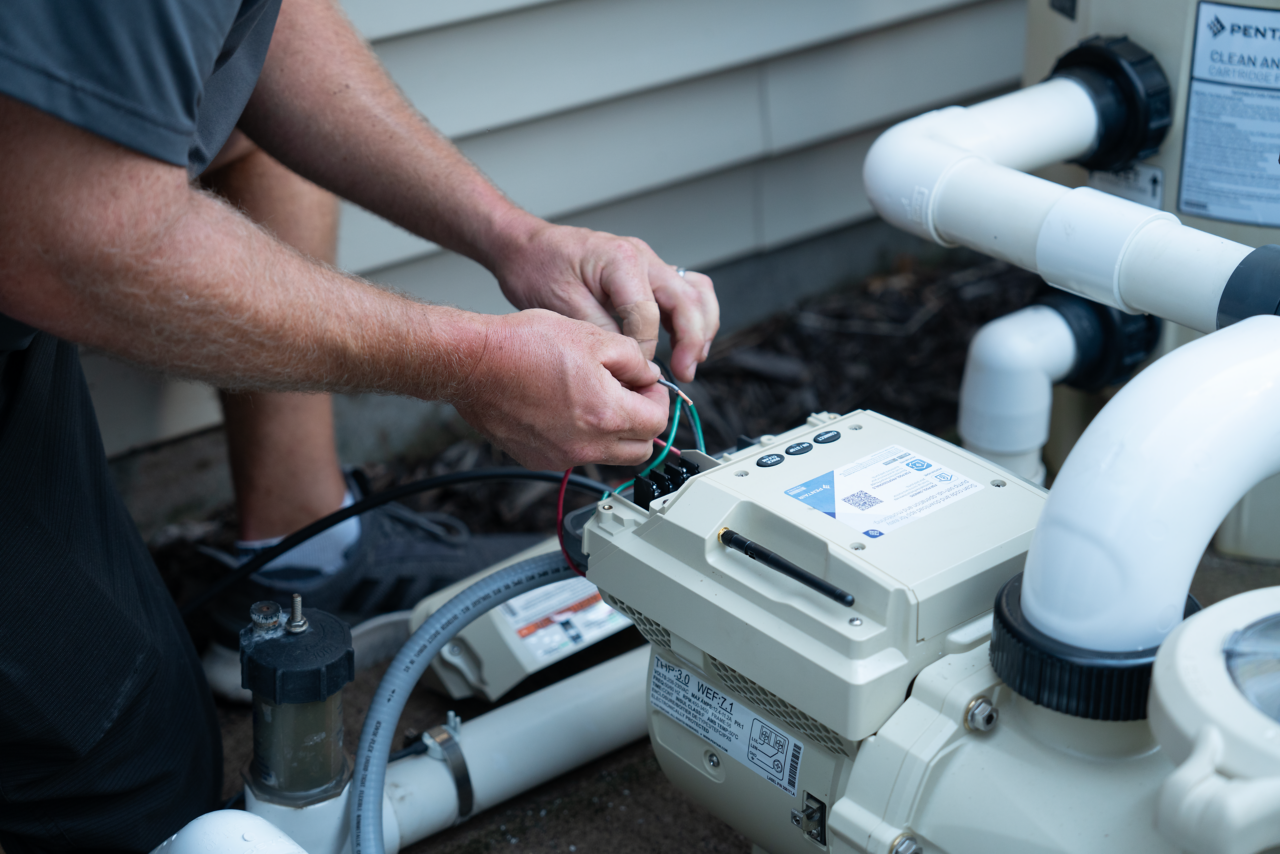

A service professional may head to a job site expecting to tackle one problem, but a thorough inspection may reveal additional or underlying issues. In addition to providing a "green light" to work on a job site's existing equipment, proper inspection helps you account for safety concerns. Before performing work on any piece of equipment, a pool pro should always:

- Locate the main electrical circuit breaker panel and identify and confirm which breaker is designated for the pool pump.

- Ensure the circuit breaker is flipped so no power is going to the system before any maintenance is attempted.

- Confirm that the system is not running before checking pipes or opening a pump.

-

Program for Short Bursts of Higher Flow

-

Variable speed pumps are more energy-efficient than single-speed pumps. Flow rate, or the volume of water that passes through the pump, is a critical calculation to determine the proper water turnover rate to maintain clarity in a pool. Variable speed pumps don’t need to run at full speed or a high flow rate all the time to do their job effectively.

In fact, running these pumps at a low flow rate (or speed) for a long period of time to circulate the chemicals and turn over the pool water is an effective way to circulate chemicals. To generate more surface water movement from the return jets and allow the skimmers to collect floating debris, the pump will need to be programmed to run at a higher flow rate for short periods throughout the day.

A well-programmed variable speed pump rather than a single-speed pump can help pool owners save energy... and lower their bills. With your help, they'll be the talk of the town. If you're looking to offer energy-efficient options to your single-speed pump customers, products like the IntelliFlo3™ VSF Pool Pump from Pentair can allow your customers to save up to 90%* on energy consumption.

-

Keep Seasonality in Mind

-

Anyone in the pool industry knows what seasonality means to pool owners. Obviously, cool or wet weather can create a sticky situation for pools, but particular seasons (like spring and fall) bring concerns like:

- Sticks

- Leaves

- Acorn

- ...And other debris

Debris like this has the potential to fill a skimmer basket quickly. When visiting a wellshaded pool during these seasons, always check the skimmer basket. Educating the pool owner is important — blockages add friction to the pool system, resulting in higher energy usage and costs. Advise them to empty the basket as often as possible to prevent blockages and to allow the pump to work most efficiently. Pool professionals should train homeowners on the capabilities, functions, and maintenance needs of their variable speed pump.

-

Optimize Circulation

-

Improved circulation at the surface of the pool allows debris to be skimmed before it sinks. As you know, programming pumps to run at higher flow rates for short periods throughout the day can generate more surface water movement from the return jets. The IntelliFlo3 has patented sensorless speed and flow technology that adjusts to pool conditions. This, combined with the ability to control from anywhere for increased productivity, makes it easy to keep a pool in prime condition. Not all pumps are created equal, so different products may require more programming or scheduling adjustments.

However, if a pump’s speed and flow rate have been adjusted but a customer is still experiencing a lot of debris in their pool, the return jets should be checked. Return jets, sometimes called eyeballs, should be arranged near the surface of the water to optimize circulation.

-

Keep an Eye Out for Leaks

-

While we're on the topic of eyeballs, keep your eyes peeled for signs of leaks. There are two types to watch for:

- Water leaks

Watching for and mitigating leaks is crucial to maintaining a variable speed pump for years to come. Putting extra stress on a pipe when servicing the filter, accidentally leaning against a piece of plumbing, or even aged O-rings can cause water leaks. If the pump’s mechanical seal between the impeller and the motor is worn out, a leak may appear in the middle of the pump. - Air leaks

Air leaks can be caused by a variety of factors. The ground shifting during changes in the seasons, fluctuating frost lines, or even UV rays that break down components in PVC can all lead to an air leak. A cracked, stretched, or aged O-ring is also a common cause of an air leak and is often a relatively cheap fix. Replacing the O-ring, cleaning the groove it sits in and applying a new coat of lubricant can often do the trick. If the O-rings appear to be intact but an air leak remains, check the pump’s PVC plumbing. Over time and when exposed to the elements, the epoxy seal can become brittle and less effective. If an air leak stems from the plumbing, caulk can patch the crack, or the plumbing may need to be re-glued.

While leaks happen, steps can be taken to help avoid them. Protect pumps from the heat by ensuring they are shaded from the sun and have ample ventilation. They should also always be protected from dirt and moisture.

- Water leaks

-

Trust Your Ears

-

One of the simplest ways to locate an issue on a pump is to listen for its hum. Pump sounds often change during its operation, but certain noises should stand out as unusual.

As we mentioned, emptying a skimmer basket can prevent blockages. In addition to checking the basket, service professionals should note any noises from the pump. A noise may indicate debris stuck in the impeller — when you hear an unusual sound, check the clearance between the impeller and the diffuser for possible debris buildup in the tight channel.

-

Go Remote If Possible

-

While servicing a drive is notoriously complex, a pump that connects with an app allows a professional to diagnose a problem more easily. Select apps will alert a professional to alarm codes that can help pinpoint the issue. If given an alarm code, a pool pro should reference the manufacturer's website or the product manual to determine the appropriate next steps.

As the industry continues to evolve and products become more connected, pool professionals may be able to remotely receive alerts notifying them of issues with the equipment at their customers’ pools. This real-time monitoring can help service professionals proactively address problems before they escalate. Depending on the alarm code, they may even be able to bring a part with them that could fix the problem on the first trip, helping professionals accomplish tasks in just one visit instead of multiple visits or calls from their customers, saving time and resources. The quick, intuitive Pentair Pool and Pentair Pro smartphone apps, for example, allow pool owners and professionals to check the pool’s operating status, configure pump speeds and limits, and monitor and operate the IntelliFlo3 using Bluetooth® wireless technology on-site or WiFi. Remote monitoring also makes it easy to adjust performance and troubleshoot issues, delivering value to customers and helping service providers grow their business.

Not only can proper service and maintenance protect the longevity of the equipment, but it can also help save pool professionals and their customers time and money over time. With these seven servicing tips in mind, pool professionals can make informed decisions and help their customers avoid costly mistakes.

*Savings based on variable speed pump compared to a single-speed pump running 12 hours per day at an average of $0.16 per kWh in a 20,000 gallon pool. Actual savings may vary based on local utility rates, pool size, pump run time, pump horsepower, pump rpm, plumbing size and length, pump model, service factor and other hydraulic factors. Individual Weighted Energy Factor (WEF) scores and savings may vary by model.

All indicated Pentair trademarks and logos are property of Pentair. Third party registered and unregistered trademarks and logos are the property of their respective owners. The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc. and any use of such marks by Pentair Management Company is under license.