- Home

- Education & Support

- Water Education Center

- Spray Nozzles Durability

How Nozzle Wear Can Affect You

Parts on your sprayer are constantly in use. They wear out and have to be replaced. The same happens with spray nozzles. Worn spray nozzles can have a significant impact on the performance of your sprayer and ultimately the crop protection chemistry they are used to apply. Modern sprayers utilize flow rate controllers to maintain a desired application volume. To do this, the flow rate controller monitors the liquid flow rate out of the boom and matches it with the ground speed of the sprayer to maintain your desired application volume. As nozzles wear, the orifices increase in size and allow for more liquid volume to pass through them. When using worn spray nozzles, the flow rate controller will compensate for the increase in flow rate by reducing spray system pressure.

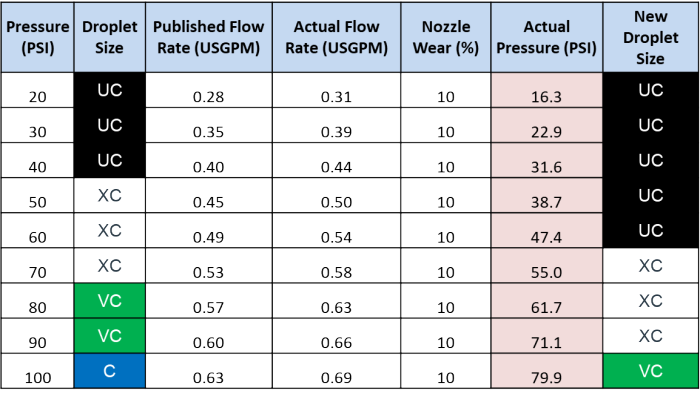

Impact on Flow Rate, Pressure and Droplet Size of 10% Nozzle Wear

Reducing spray system pressure can impact spray nozzle performance by increasing median droplet size and affecting coverage and spray pattern distribution. When spraying at lower pressures, worn spray nozzles can develop pressure reductions below the minimum pressure. If this happens, it can create reductions in spray angle, also known as pattern collapse. The resulting outcome is uneven spray coverage across the boom. You can also experience increases in droplet size resulting from pressure reductions in worn spray nozzles. These increases in droplet size can have a negative effect on spray coverage. If the pressure reduction is significant, it is possible to see pattern collapse that can negatively impact spray coverage and application distribution across your fields.

How can you avoid the performance issues related to worn spray nozzles?

Flow rate in gallons per minute (GPM) at 40 psi is used to measure the percentage wear of a spray nozzle. By collecting the flow through nozzles at 40 psi, we can determine the level of nozzle wear by comparing the captured volume versus the manufacturer stated flow volume for that spray nozzle. The application industry recommends changing nozzles when they reach 10% wear, or an increase in flow rate of 10% greater than the manufacturer stated flow rate.

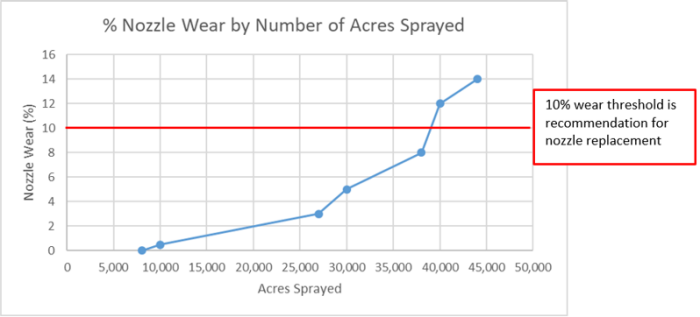

To answer the question of how long spray nozzles last, Pentair Hypro supplied Pentair Hypro 3D Nozzles to applicators in order to produce field wear and tear. For the 2019 spring and summer seasons, these nozzles were used to apply herbicides and fungicides to thousand acre increments of 8, 10, 27, 30, 38, 40 and 44 to produce nozzle sets with varying degrees of wear.

Nozzles were then retrieved and their respective flow rates were collected using a bench top spray table with pressure set to 40 psi. A handheld SpotOn calibrator was used to collect and measure flow rate. Flow rates in gallons per minute were recorded and used to calculate percentage wear by number of acres sprayed.

Figure 1. Effect of Field Spraying Acres on Percent Spray Nozzle Wear

Replace Nozzles...

If the flow from a nozzle varies more than 10% above or below the average of all the nozzles or the factory stated flow at 40 psi.

Choose your Pentair Hypro Spray Nozzle

Nozzles used to apply 8,000 acres of crop protection chemistry showed no signs of wear present. Significant signs of nozzle wear were not detected until nozzles had applied 30,000 acres of crop protection chemistry, when 5% wear was recorded. The 10% wear threshold was crossed with nozzles that applied 40,000 acres. Nozzles seeing 40,000 acres of use exhibited a 12% increase in flow rate compared to a 3D100-04 nozzle that is new (Figure 1).

Coefficient of Variation (CV) is a metric used to quantify the uniformity of a spray pattern. A higher percent CV number indicates lower uniformity of spray droplet distribution. Areas under a spray boom will receive a higher dose, while other areas will receive a lower dose, which is the goal. For agricultural spray nozzles, the accepted threshold to remain under is 7% according to ISO 16119-2:2017.

The same spray nozzles that were used for the flow rate and wear testing were also tested to determine their uniformity of spray pattern distribution. Nozzles used on 44,000 acres exhibited an 80% increase in the spray pattern CV compared to the same nozzle when new. When new Pentair Hypro 3D-04 Nozzles displayed a CV of 3.1% at 40 psi, however, after 40,000 acres of use these same nozzles displayed a CV of 7.5% at 40 psi. This CV after 40,000 acres of usage crosses over the desired threshold of 7% CV for agricultural spray nozzles. Increasing levels of CV will reduce the accuracy and precision of an application and may have potential if left unchecked to allow pest control overspray to occur.

From this field and lab testing, we have determined that 40,000 acres of use should be considered as an expected lifespan for agricultural spray nozzles made of polyacetal. Once you reach 40,000 acres of use, it is recommended to check spray nozzles for wear and condition. Such check should be performed at 5,000 acre intervals until flow rate increases to 10% above manufacturer stated flow rate at 40 psi.

SpotOn® trademark and logos are the property of SpotOn®.